Ceramic Binder Definition

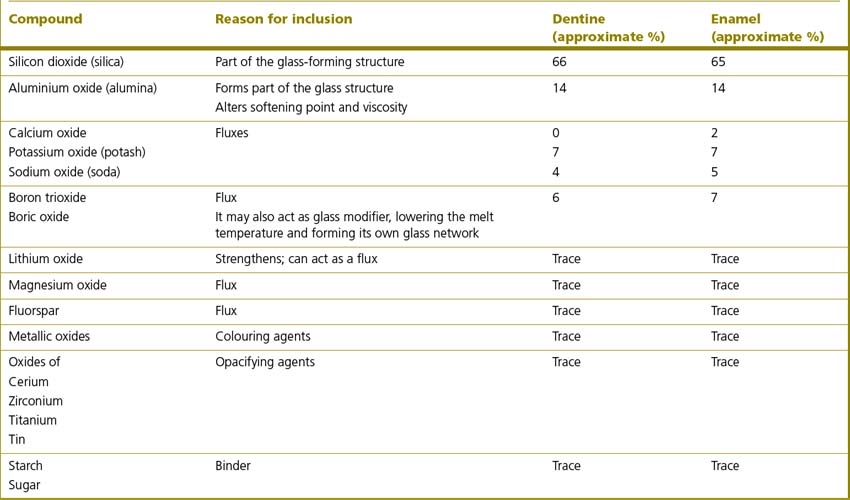

Ceramic slurry is obtained by mixing ceramic powder carrying vehicle binder and dispersant to produce uniformly dispersed ceramic slurry.

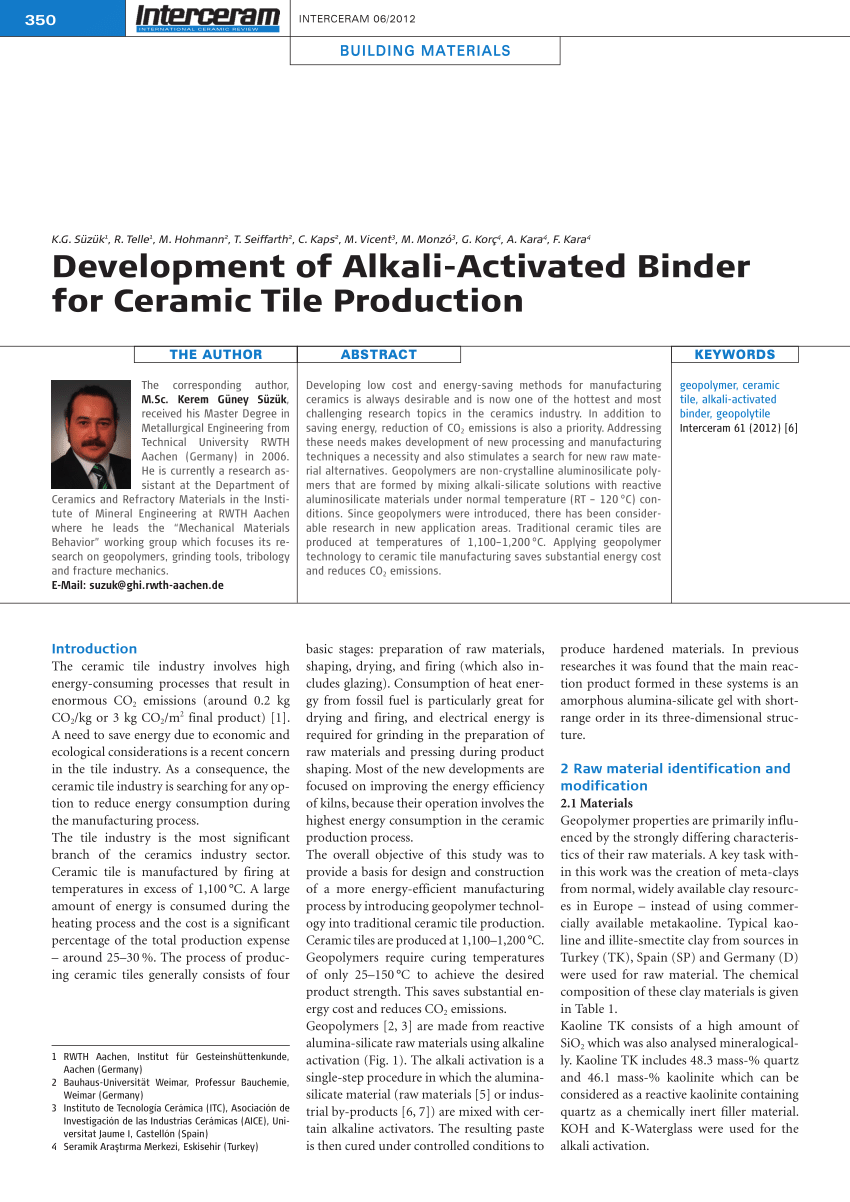

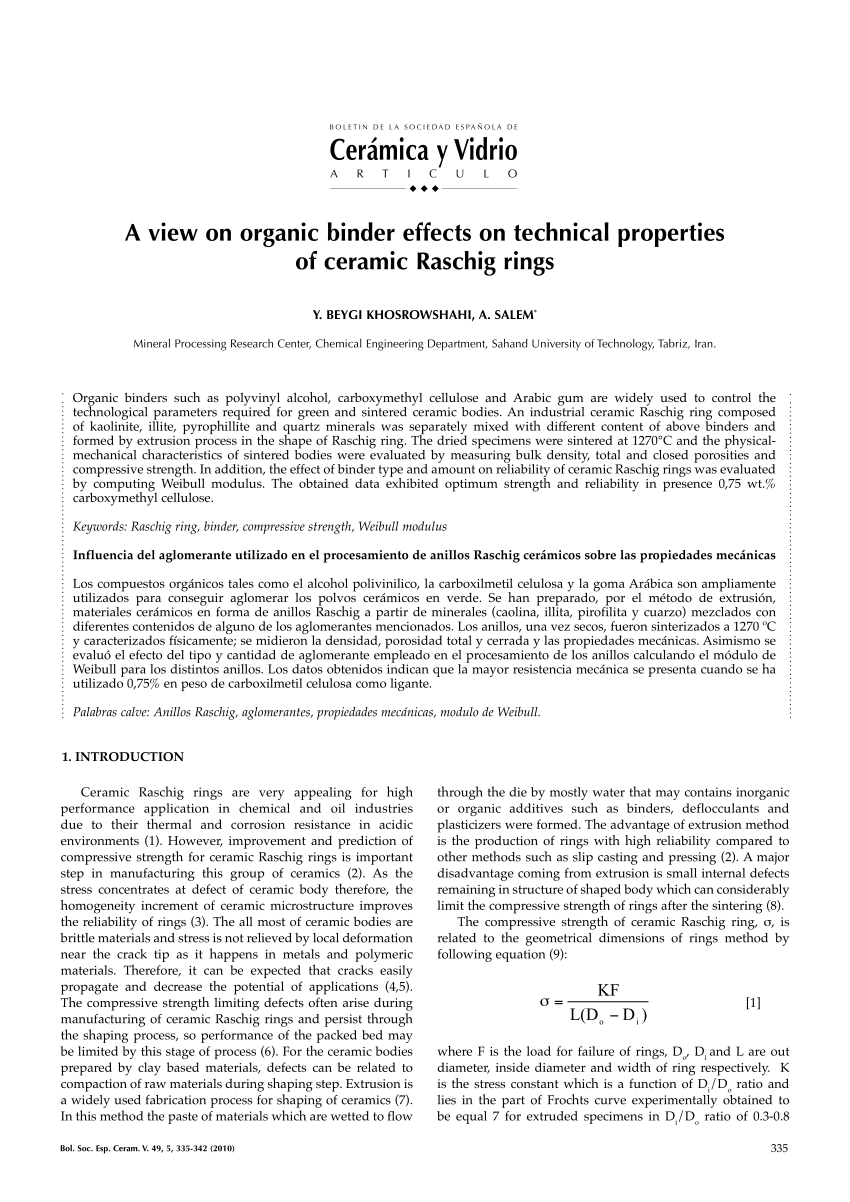

Ceramic binder definition. It is important to optimize the slurry composition in order to obtain high green density low green shrinkage and sufficient green strength to produce defect free demolding. An overview of the major types of organic and inorganic binders used in various different ceramic industries. They reduce the friction between the particles between granules and between the powder compact and the walls of the die. An inorganic binder such as kaolin don t burn off instead they become a part of ceramic.

The ceramic parts contain only 2 5 vol binder solids basis which increases the strength of the ceramic systems by at least a factor of 8 while the strength of al2o3 components increases by a. Excellent binder for producing high temperature protective coatings and refractory and chemically resistant adhesives and patching materials. Fully cures at low temperatures and sets up in thick cross sections when properly formulated. Binders are substances that improve the mechanical strength of green ceramic bodies so they can pass through production steps before firing without breakage.

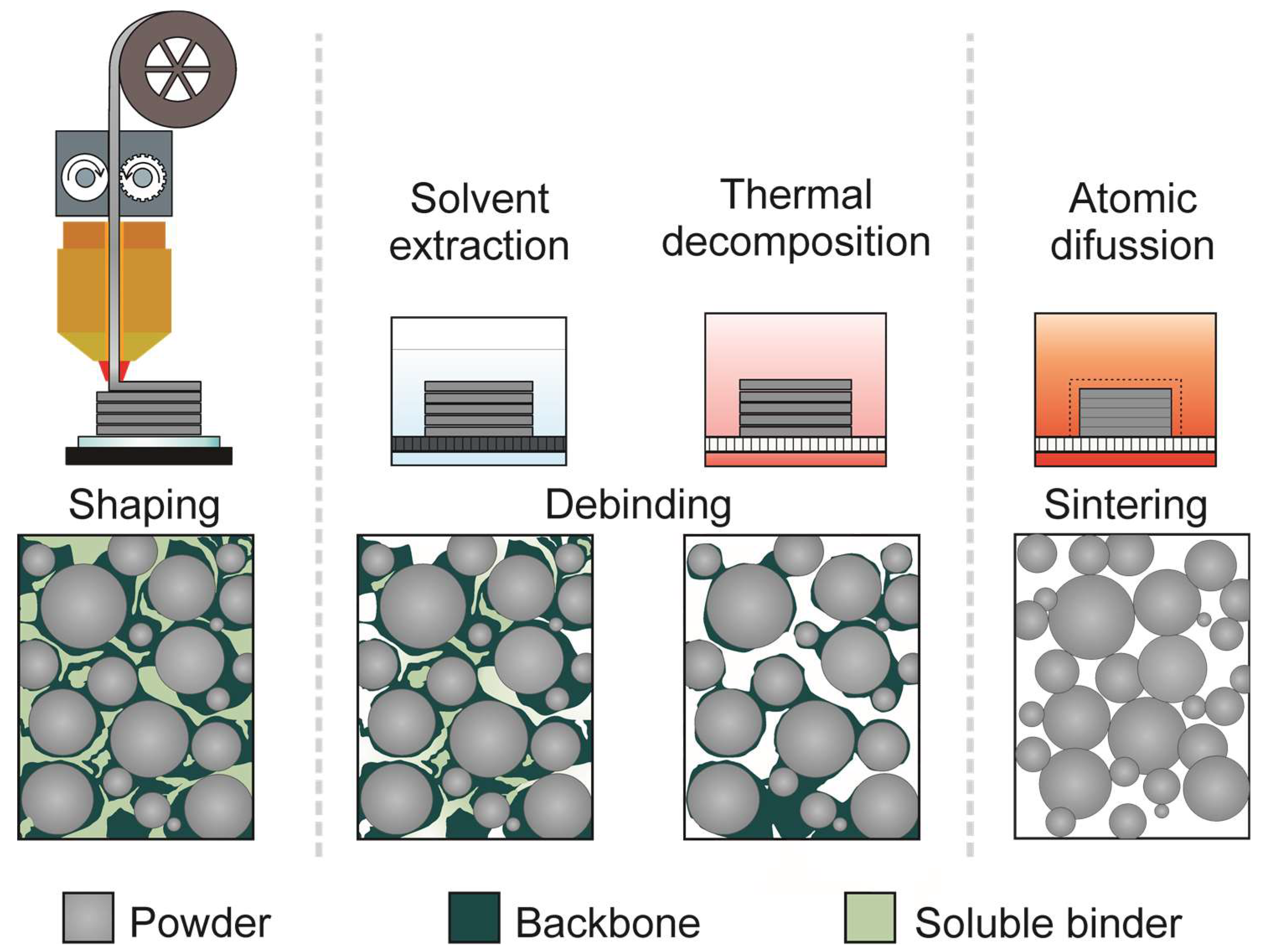

Different from material jetting the binder jetting printed object is self supported within the removable powder bed fig. The pattern is designed with the materials already mentioned plastic wood metal etc. The ceramic molding process can be summarized in 7 steps. The binders are particularly useful in tape casting processes for the manufacture of thin ceramic sheets which are used as substrates for electronic packaging.

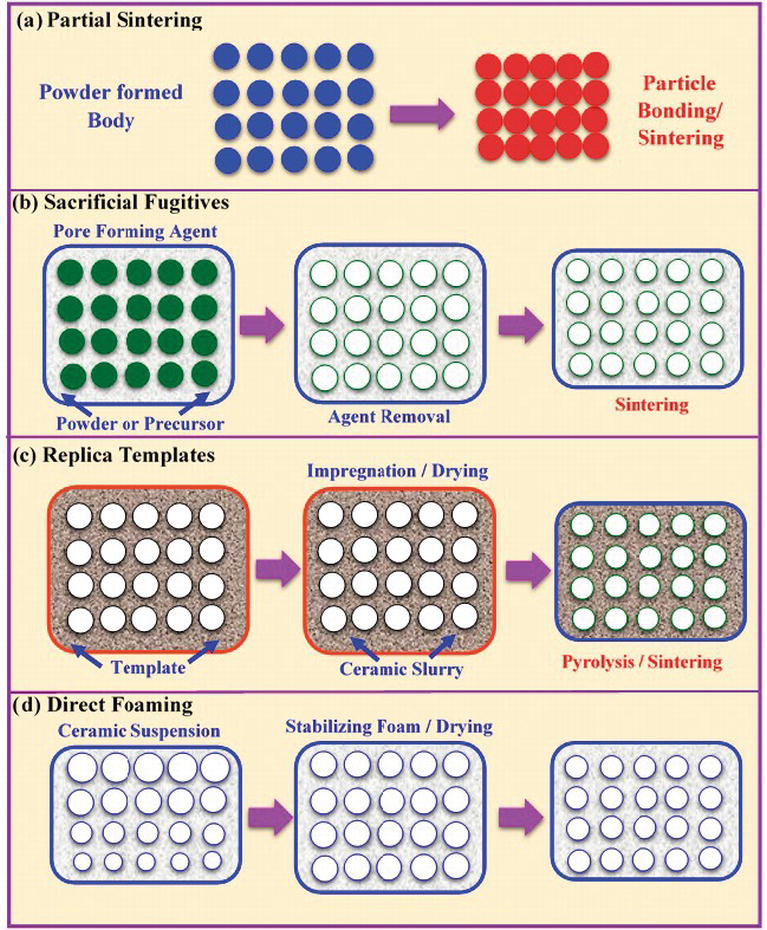

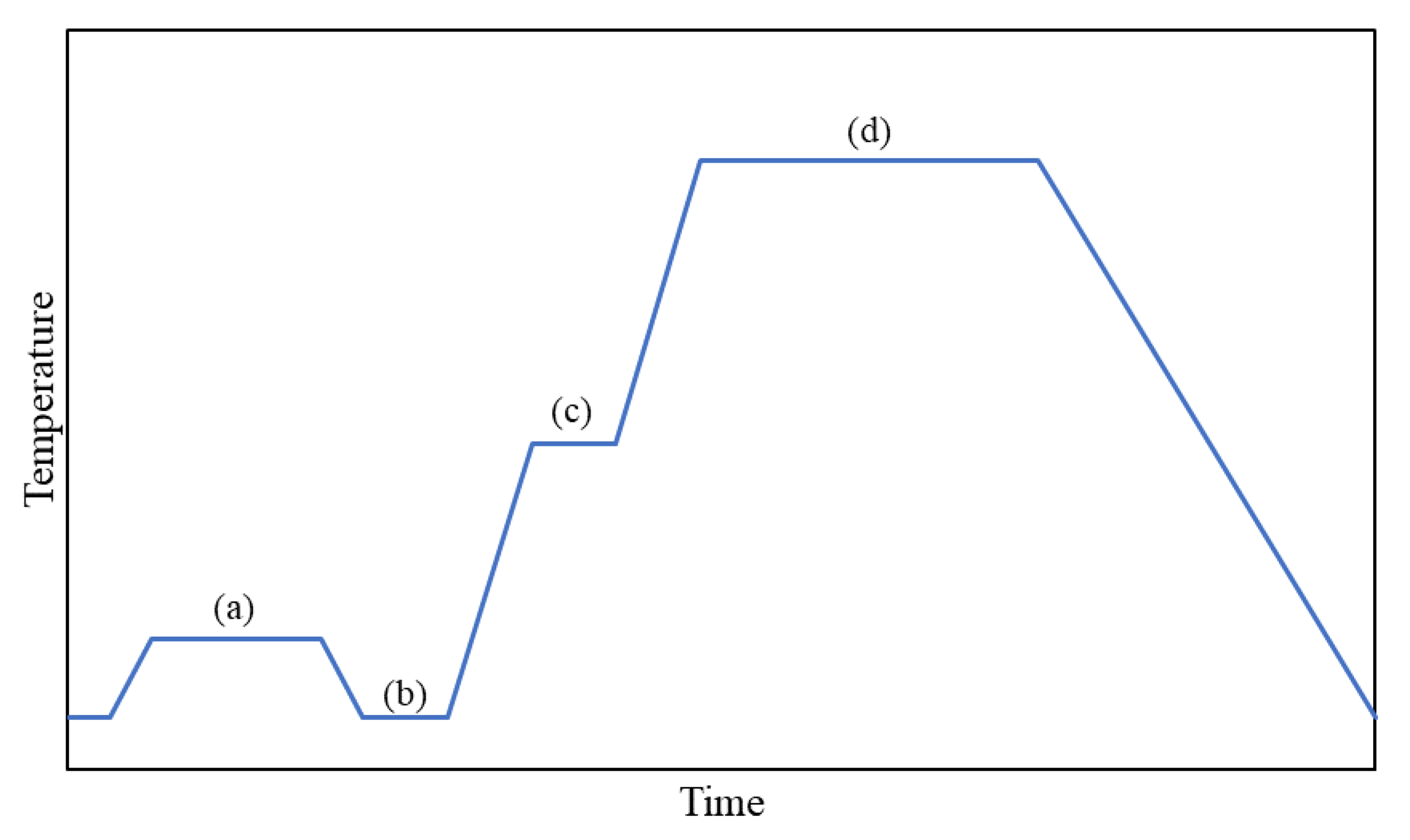

The resulting green part must later be sintered in a kiln. Many materials can be used as a pattern because most of them support the low temperature which is used in the ceramic molding process. The compaction process permits an efficient production of parts to close tolerances with low drying shrinkage. A basic solution compatible with most ceramic and metal powders.

Binders for ceramic bodies description. Binders for ceramic products are provided which are crosslinkable and impart improved tensile strength to ceramic green bodies. Some elements such as carbon or silicon may be considered ceramics ceramic materials are brittle hard strong in compression and weak in shearing and tension. A ceramic material is an inorganic non metallic often crystalline oxide nitride or carbide material.

Binder selection depends on the type of pressing that is to be done. The mix is injected into a binder.